- Quality control in PPM and micrometer measurement

- Analysis of surface defects

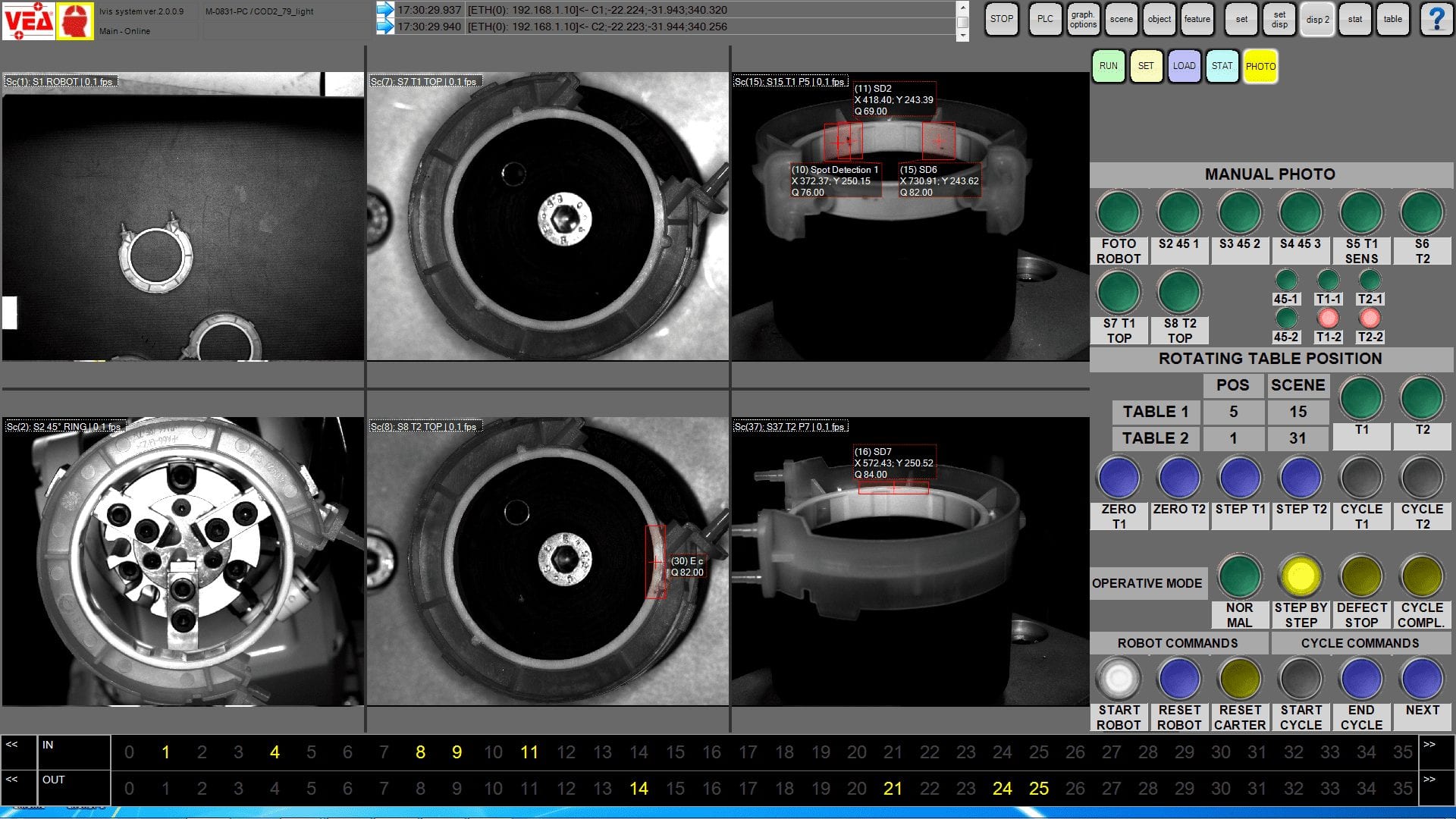

- Robot guidance with HMI

- up to 500 photos/sec processed

- Economical and financeable Industry 4.0

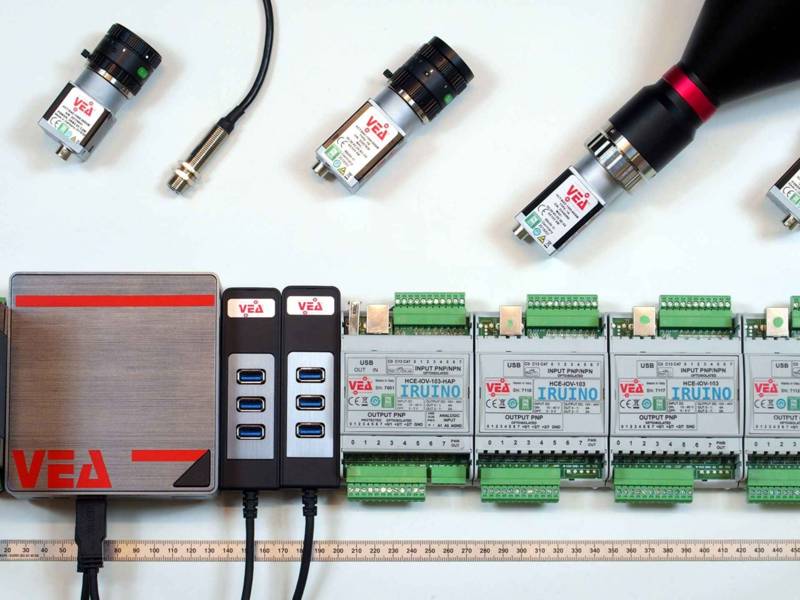

MACHINE VISION SYSTEMS

Compact, modular, expandable and economical.

IVIS è "the scalable vision system" with such extensive modularity that it can replace from sensors of vision up to the most complex vision systems.

IVIS è the integrated vision system which includes a powerful "Vision Plc" complete with operator panel easily configurable.

Thanks to these features and the wide variety of software packages and cameras that can be integrated, the IVIS vision system is able to adapt to all kinds of needsIt can easily and inexpensively replace a vision sensor and, where necessary, transform itself into a powerful, high-performance system.

Since 2007, VEA has been using algorithms in "hybrid logic", which adopt a pre-set supervised learning based partially on neural network, and partially on statistical and mathematical logics to reinforce its stability.

In 2018, VEA developed the proprietary technology. Regulated Machine Learning. It is a series of hybrid algorithms that use, in a complementary way, Deep Learning logics that learn the case history of the defects, and "supervision" logics that increase the reliability of the recognition.

It is also possible to have pre-constituted learning "packages" that avoid long and expensive learning sessions at the expense of the client.

PRODUCTS

HQV-PPM

Vision systems: HQV-PPM

It's the top of the integrated vision systems EVA. All products in this series have the satisfaction or refund guarantee on your application and are installed directly by VEA vision professionals who have been operating for at least 5 years.

The HQV-PPM machine vision systems are configured directly by the VEA technicians to ensure maximum functionality and reliability.

In this series are used the most advanced algorithms of the latest generation or are built optimized algorithms for your application.

These vision systems can be certified to ISO standards with very high scores and ensure reliability in the order of some PPM (Parts Per Million).

HQV

Vision systems: HQV

It's the series of integrated vision systems with high reliability with the best value for money.

In this series are used hybrid logic algorithms that allow high precision and reliable image analysis. HQV machine vision systems are directly configured by VEA technicians to ensure maximum functionality and reliability. These vision systems can be certified to ISO standards and achieve excellent scores.

VEDO

VEDO: the best-selling low-cost system.

VEDO is the best-selling series of scalable, integrated vision systems due to its outstanding price/performance ratio.

This series has been specifically designed for anyone who wants to use a vision system directly in a simple and natural way. These vision systems have an extremely affordable price, are easily configurable and maintain the same graphical interface and most of the algorithms that have decreed the success and reliability of the HQV series.

VEDO vision systems, while retaining all the power and flexibility of a true vision system, are priced comparable to a vision sensor.

TYPES OF CONTROLS

Quality control in PPM

Multiple quality checks simultaneously, e.g. correct assembly, presence of defects, legibility of marks and lettering.

Surface analysis

A series of particularly advanced algorithms allow to control surface defects such as barrel, porosity, opacity, grit, dirt, cracks, flaking or scratches.

Measurement in production line

Measurements can be made directly during production by checking the 100% of the parts. The accuracy is micrometric, repeatability and accuracy are calculated in real time to compensate for changes in the environment.

Robot guide

The VEA robot guide is the software module which, using advanced logic, both for 2D and 3D gripping, allows the correct identification of the object in space.

Reading Datamatrix, OCV OCR

You can read the codes printed on the part being inspected, save the image, and analyze the information it contains. These machines can also be equipped with a marking system to objectify the product.

IVIS "C" SERIES: THE POWERFUL AND PERFORMING MACHINE VISION SYSTEM

Vision systems IVIS have been designed specifically with the aim of solving real problems in industry and to reduce costs and time for vision system integrators.

The scalar architecture allows to realize from the simplest applications to the most complex vision systems, using a single programming language.

The vision system IVIS through its own software modules, is able to execute quality controls, surface analysis, measures very high precision, ocv-ocr reading, datamatrix e robot guide.

VEA designed the machine vision system IVIS from very high quality and performance at a cheap price.

VEA simplifies the management of quality control using vision systems IVIS.

They are fully configurable through a multi-touch operator panel and offer the total control of the vision system and a complete overview of the ongoing analysis, as well as the results in real time.

I scalable vision systems are increasingly used because they combine performance high at a cheap price. They also allow operators to learn a single vision system thus avoiding learning the operation of a multitude of vision sensors and smart cameras.

DIMENSIONS AND ARCHITECTURE

The unit basic IVIS C-Series is only 11 x 11 x 5 cm, is compatible with the almost all industrial cameras in commerce.

From the models of micro-cameraas small as an M12 sensor, up to 10 Mpixel cameras, for up to 32 cameras that can be connected.

L' IVIS unit is connected to a touchscreen monitor replicating a expeller-operator HMI and a 1mSec PLC scan to which they connect several I/O modulesfor a total of 512 inputs and 512 outputs.

The high processing speed, 500 acquisitions per second, allows you to make continuous checks without photocells, making it ideal for selection systems.

They always come consulting and training proposals to allow the staff to interact with the system at their best.

VIDEO GALLERY

specifications may change without notice