ILLUMINATORS FOR VISION SYSTEMS, LAST GENERATION, MODULAR, TECHNOLOGICAL, ECONOMIC, SELF-SUPPORTING

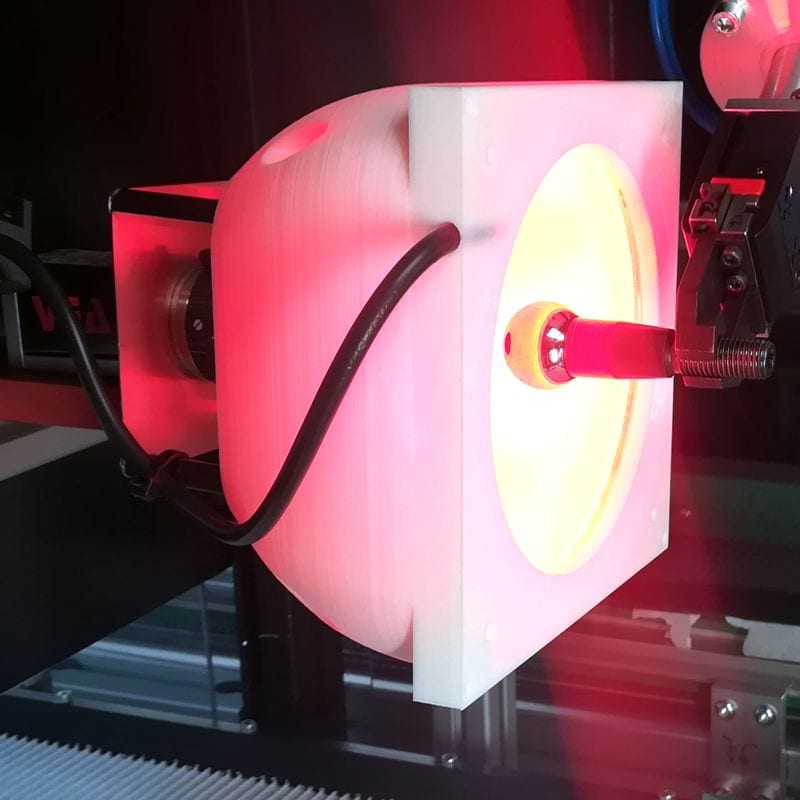

LEC-C illuminators are designed to find lighting solutions easily, quickly and economically, without the need for external supports.

The use of the latest technology makes it possible to achieve remarkable performance in confined spaces with unique ease of assembly and connection.

They are also supplied as a kit contained in a practical case.

The hundreds of lighting combinations that can be achieved with these kits allow you to solve complex vision problems.

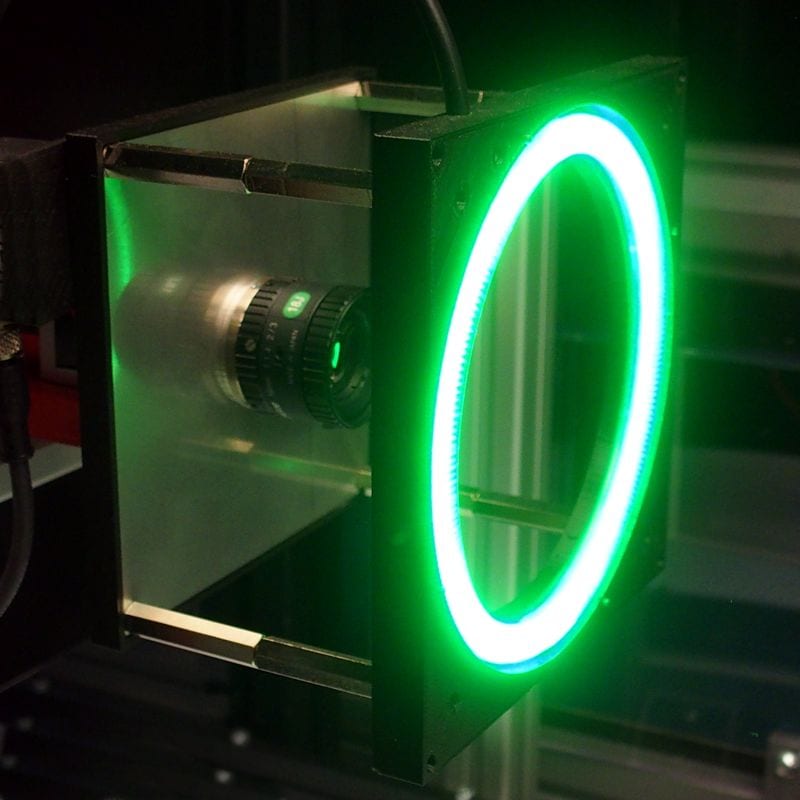

These illuminators are successfully used on complex vision systems as well as vision sensors and smart cameras.

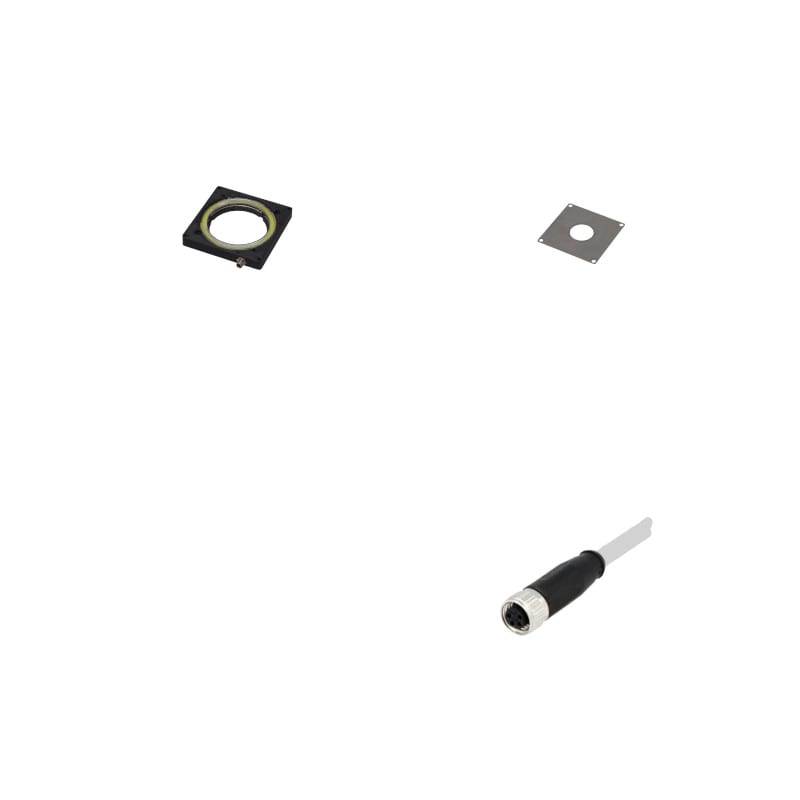

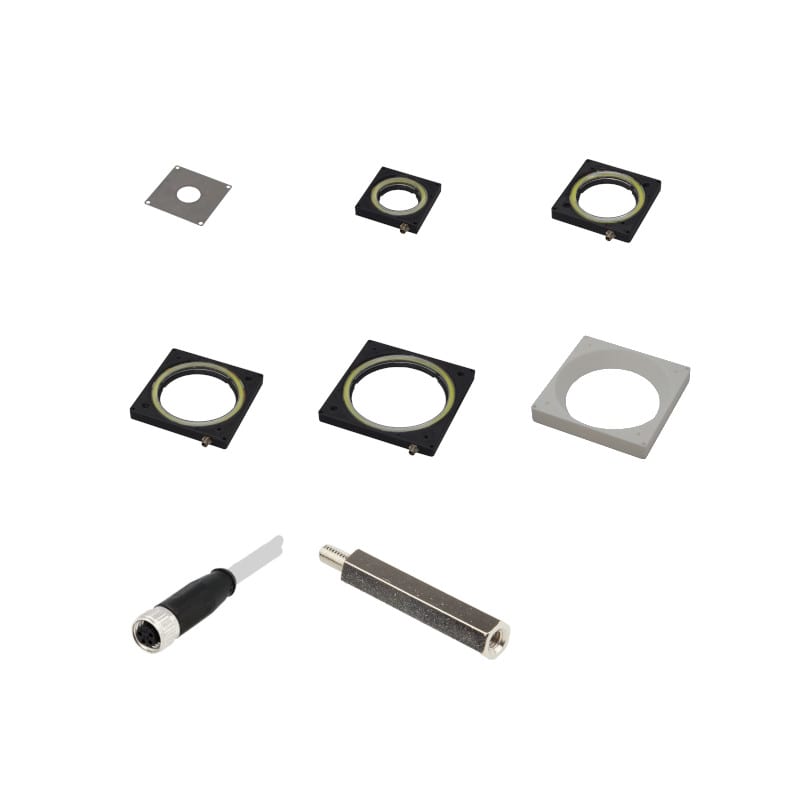

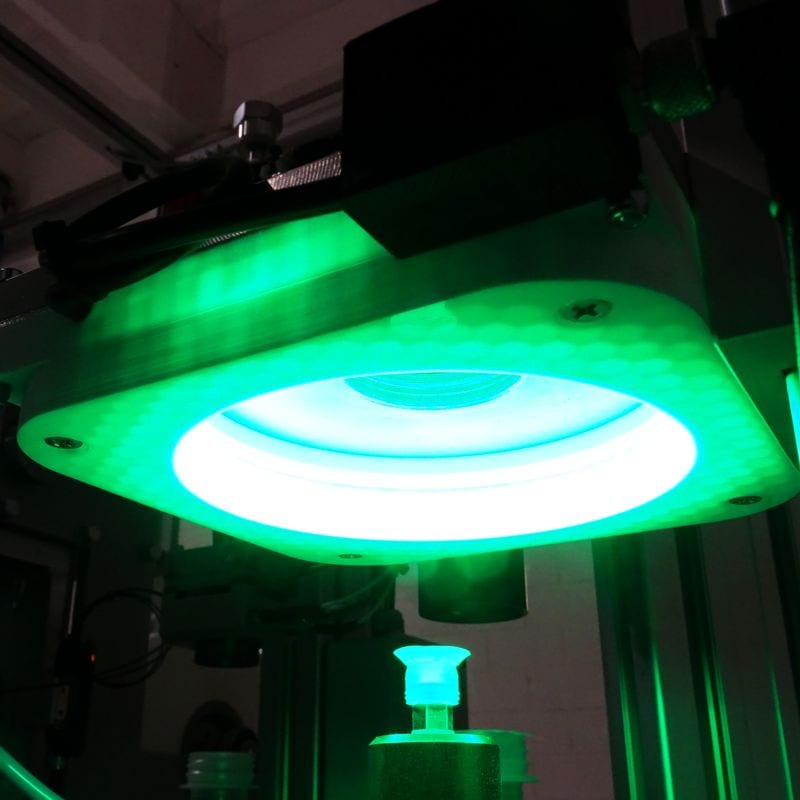

Low cost kit cases complete with illuminators for machine vision, dome, angle rings, brackets, spacers, power supply and cables to experience all lighting conditions

Case HCL-LEC-KIT-18C for C-mount cameras

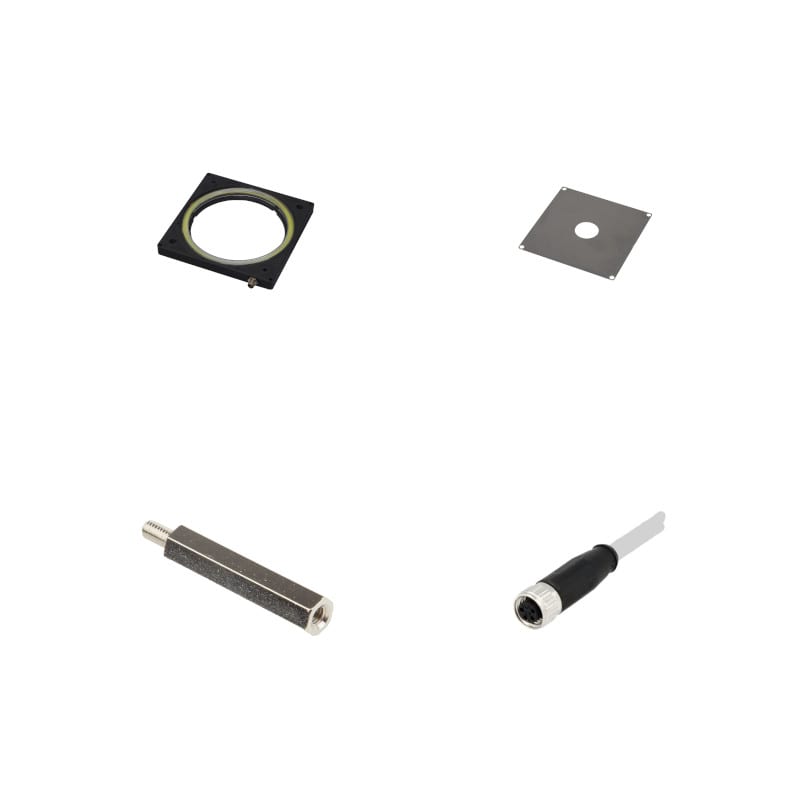

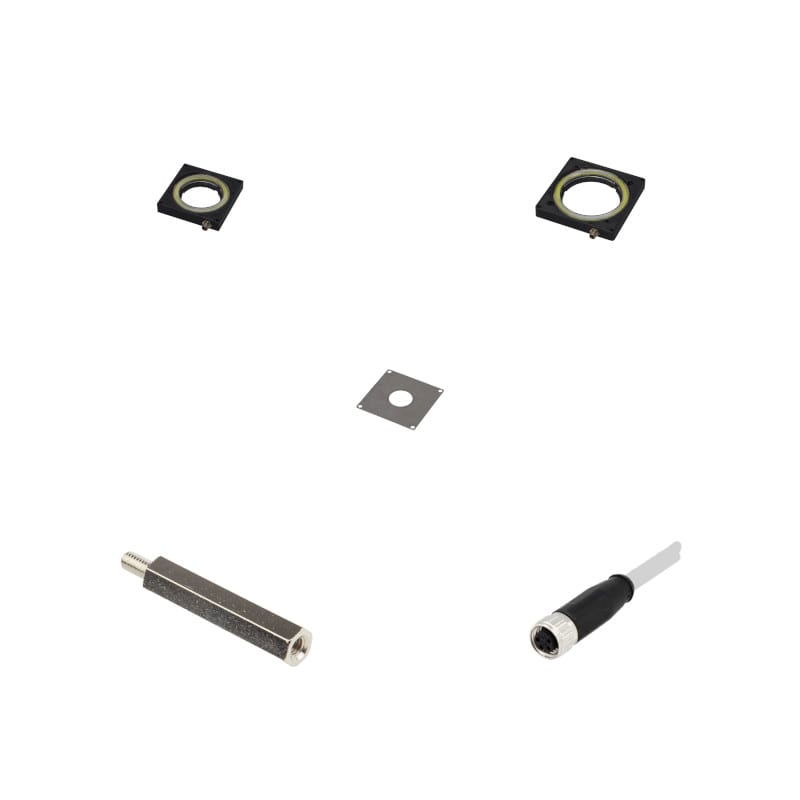

It consists of a briefcase with the following materials:

- 4 ring illuminators with integrated multi-voltage electronics (12 -24V) diameters 60, 80, 100, 120 mm

- 4 M8 connection cables

- 1 dome diam. 120 mm

- 1 low angle ring 0° (90° with respect to the optical axis) diameter 120 mm

- 1 low angle ring 30° (60° with respect to the optical axis) diam. 120 mm

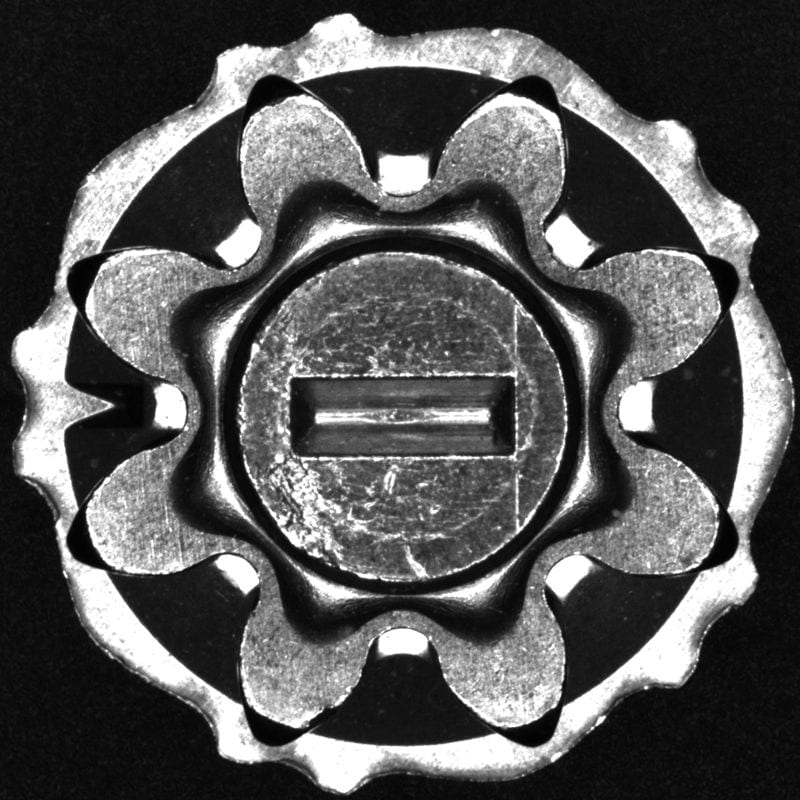

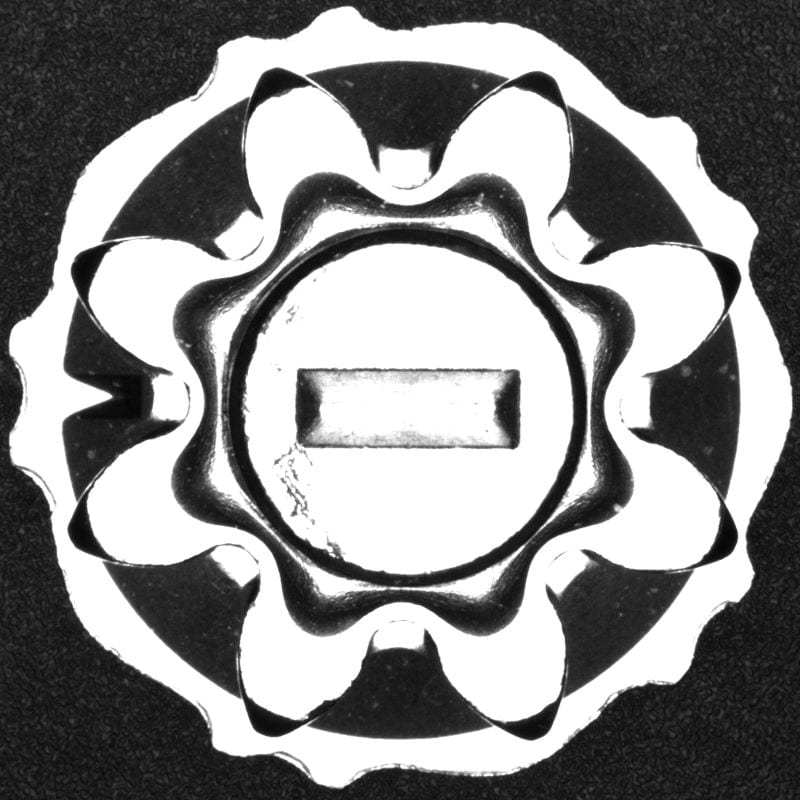

- 3 adapters for C- or CS-mount optics adaptable to the 4 illuminators

- 1 adapter from 60 mm to 100-120 mm diameter illuminator

- power supply 90W input 110-220 VA AC with 2 screw-less 5-pin lever connectors to connect all 4 illuminators

- 4 cables with M8 connector

- kit of screws and spacers

- Compatible:

- C-mount cameras - CS

- Balluff BVS-SC BVS-CA

- Cognex In-Sight 8000

- Datalogic MX-E

- Epson Compact Vision CV1 / CV2

- Festo SBRD, SBSC

- Keyence CV-X, XG-X

- Omron Xpectia

- Wenglor B50S011-014

As an alternative to C-mount lens adapters, kits with adapters are available for these products:

- Cognex In-Sight 2000, 5000, 7000, 9000

- Datatlogic P1X

- Festo SBOx-Q

- Ifm O2D, O2V

- Keyence Series IV

- Omron FHV7, FQ-M

- Sensopart V10, V20, V10C, V20C

- Telemecanique XUW

- Wenglor B50S (except 011-014)

- Others on request

LEC-C are innovative illuminators for machine vision systems using state-of-the-art technology.

These modular, lightweight, self-supporting, low-cost illuminators with integrated electronics are a real revolution in the field of machine vision.

IIluminators for industrial vision systems: features of VEA solutions

The technology that makes the difference

- Thickness of each module only 12.5 mm

- Very light (from 37 g), it can be mounted directly on robotic arms.

- Self-supporting: does not require external brackets, mounts between the lens and the camera.

- Designed to withstand vibrations over 10 G.

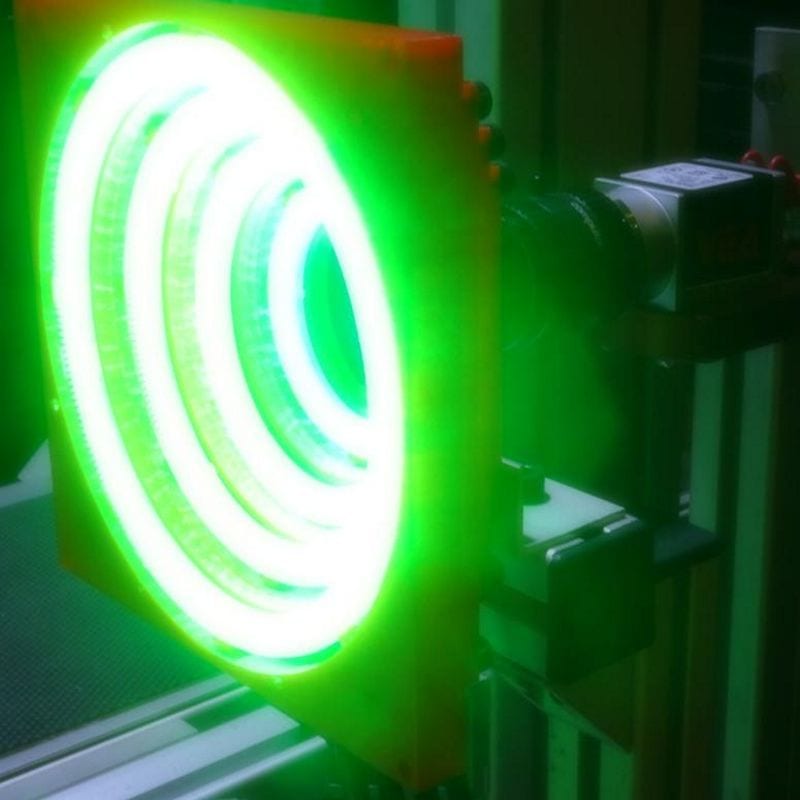

- Powerful homogeneous light beam thanks to FDC-LED technology and PC correction lens without the use of diffusers that reduce brightness.

- Stabilizing electronics integrated in the illuminator.

- Complies with the latest ISO and EN machine directives.

The reasons for our technology

- Why is the structure made of plastic?

The oversized surface graphene/carbon polymers allow to dissipate the heat of the LEDs in an excellent way, they are light, resistant and comply with machine regulations. - Why do they have control electronics inside?

To make the brightness constant even if the input voltage varies or the LEDs become hot. They also do not need external controllers. - Why do you use FDC-LED technology?

For more brightness, longer life of the LEDs and more uniform light.

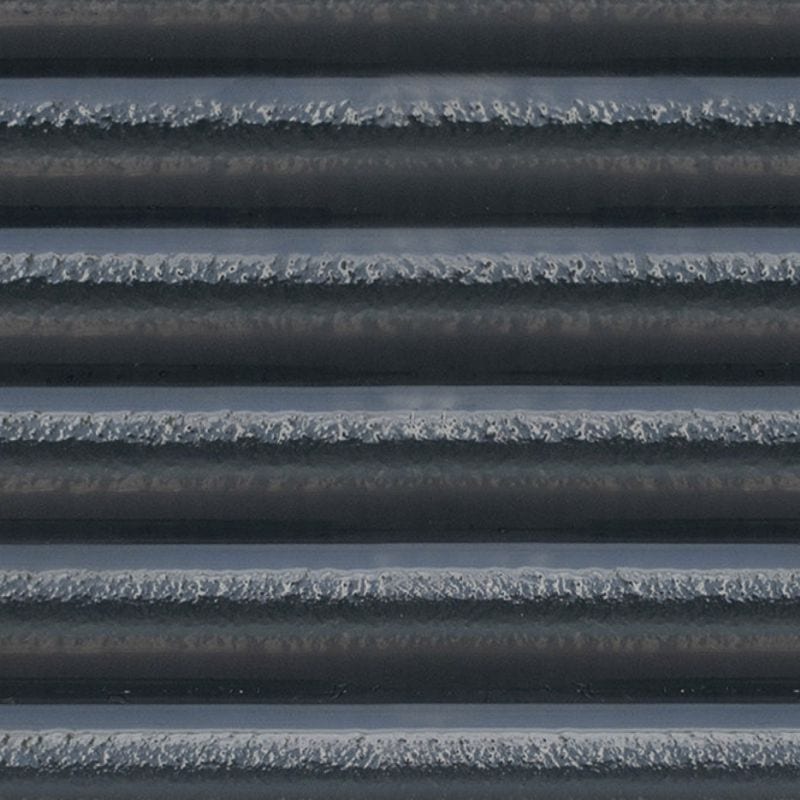

Graphene/carbon polymer structure

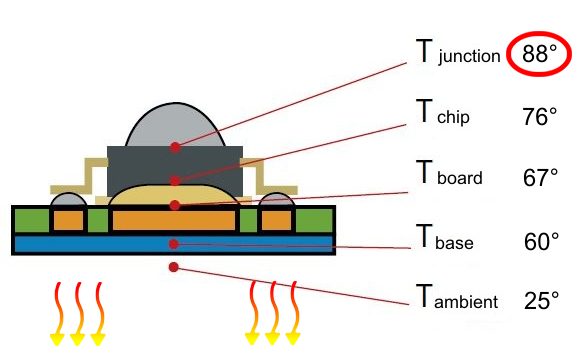

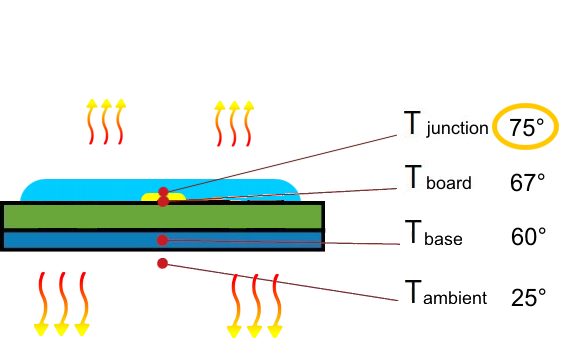

The graphene/carbon plastic polymer is a thermally conductive compound that allows a controlled dissipation especially in natural convection regime exploiting the anisotropic behaviour of the material. The realization with FDM technology (Fused Deposition Modeling) allows to design the structure of the illuminator in order to optimize the dissipation through increased surfaces and convention channels. The use of graphene and carbon is justified by their very high thermal conductivity which can reach 5000 W/mK for graphene and 2000 W/mK for carbon. Definitely high when compared to copper (390 W/mK) or aluminium (200 W/mK).

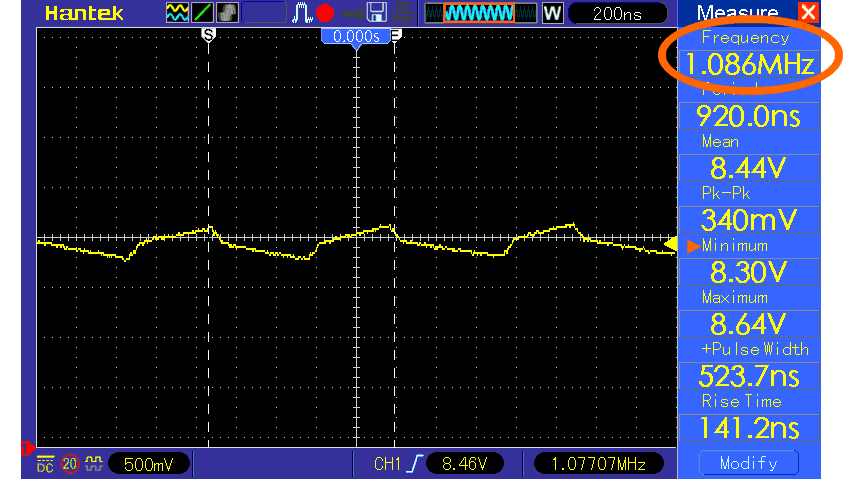

Integrated electronics in the illuminator

Complies with the guidelines for automation systems

The LEC-C series is a recent project that takes into account the current guidelines for illuminators installed on automation systems.

- EN 62471:2008 (photo biological risk)

The luminous intensity of the LEC-C series has been designed to comply with this directive. - ISO 13732-1:2009 (Machinery Directive on operator thermal risk)

This standard provides a maximum temperature threshold for contact times of less than 1 minute of 51° for metal and 60° for plastics

The choice to use a graphene plastic polymer allows to fall within this standard even with an ambient temperature of 35°. - ISO 15066:2016 (collaborative robots)

The shape with rounded edges and the plastic material make these illuminators suitable for installation on collaborative robot arms.

FDC-LED: Full Dissipated LED Chip

The latest FDC-LED technology ensures complete heat dissipation in every direction.

The multiple LED chips are connected to each other to form a single unit and incorporated completely in heat dissipating material.

The classic double soldering of the classic SMD led (chip on metal and metal on printed circuit board) is replaced by direct soldering of the chip on the printed circuit board, thus eliminating a thermal bridge.

Moreover, all the chip is drowned in a transparent conductive gel of generous size that allows a good heat dissipation even on the illuminated side, unlike the classic LED with small plastic cap.

The LEDs have a higher light output because a better thermal dispersion is guaranteed.

In addition, a great uniformity of illumination is obtained due to the total coverage of phosphorus over the entire module, the presence of the single light chip is difficult to recognize.

Lowering the temperature of the LED junction extends the life of the component.

Colours

The HCL-LEC-C series is supplied in the following colours in prompt delivery:

- White

Other colors available:

- Metrological white (series of wavelengths optimized for sub micrometric measurement with subpixeling technology, this color is designed to cancel the speckle effect)

- Red

- Yellow

- Metrological green (wavelength used in classical metrology instruments)

- Blue metrological (high frequency wavelength used in sub micrometer measurements)

DOWNLOAD

ATTENTION: at the moment the download only works when selecting the ITALIAN LANGUAGE

The suffix indicates the language of the document.

specifications may change without notice